HOME > What is the AQB Implant? > Recrystallized HA coating

Currently, our implants can be divided into two types according to the materials. |

||

| - Titanium implants | - A prolong period of time for the implant to take to the bone | |

| - HA-coated implant |

- HA’s affinity for bone is higher than that of titanium. - HA decomposes due to heat during coating. - The high purity, crystallized coating layer is difficult to make. - HA melts and peels easily within the body. - The weakness is the brittleness. |

|

The recrystallized HA thin-layer-coated |

||

- A 35-μm thick coating layer seldom peels off structurally.

- A nearly complete monolayer of HA with few decomposing products at high temperature.

- HA is highly crystallizable.

- HA micro-crystallizes into needle- and hexagonal cylinder-like shapes on the surface.

- The coating layer has a Ca/P molar ratio of 1.66, which is similar to the stoichiometric ratio of pure HA.

- It will not alter the pH of saline.

- It is less soluble in vitro and in vivo.

The main component of bones and teeth is hydroxyapatite {HA: Ca10(PO4)6(OH)2},

one of the calcium phosphates, which has high affinity for body tissue and binds to bone in the body over time. However, HA seldom crystallizes without the application of high temperature and pressure.

HA-coated titanium and titanium alloy implants may elute metal components when used in the body over a long period of time. We developed recrystallized HA-coated implant by pursuing adequate safety. The AQB Implant decomposes less at high temperature because of the thin-layer coating from plasma spraying of bone conductive tricalcium phosphate

{TCP: Ca3(PO4)2} followed by conversion into the recrystallized HA coating layer through hydrothermal treatment (Japanese Patent No. 3198125).

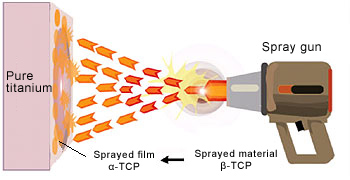

Conventionally, plasma spraying of HA powder on the surface of titanium base material creates the hydroxyapatite (HA) coating. Meanwhile, plasma spraying of low-temperature tricalcium phosphate (β-TCP) powder makes the recrystallized HA coating.

Recrystallized HA coating process provides higher crystallizable HA compared to conventional HA coatings.

| 1. Pre-treatment (mirror-like finish and sandblasting) The titanium surface is sandblasted followed by washing with acetone. |

||

|

|

2. Plasma spraying Plasma spraying of tricalcium phosphate (β-TCP) powder, which is stable at low temperature, creates the recrystallized HA coating.

|

|

| 3. Hydrothermal treatment Applying α-TCP characteristics where it can be converted into HA after hydrolysis and placing sprayed implants under hydrothermal atmosphere to convert α-TCP into HA (recrystallization). |

Recrystallized HA coating process provides higher crystallizable HA compared to conventional HA coatings.

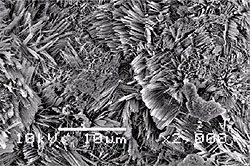

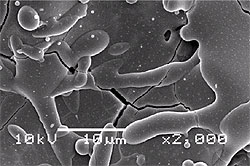

▼ Layer prepared through the recrystallized HA coating process

The HA is highly pure as shown by the needle and hexagonal cylindrical crystals on the surface, which are characteristic of HA.

The HA is highly pure as shown by the needle and hexagonal cylindrical crystals on the surface, which are characteristic of HA.

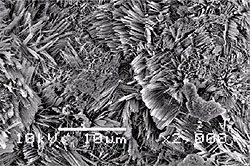

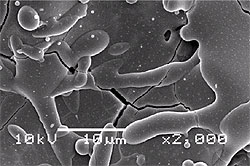

▼ HA-sprayed layer

HA reaches the base material after decomposing and melting from the high temperature and rapid cooling process accompanied by plasma spraying; therefore, HA is vitrified as shown in the figure above. And, HA contains CaO with a strong alkali as a decomposition product; therefore, it is less crystallizable and pure.

HA reaches the base material after decomposing and melting from the high temperature and rapid cooling process accompanied by plasma spraying; therefore, HA is vitrified as shown in the figure above. And, HA contains CaO with a strong alkali as a decomposition product; therefore, it is less crystallizable and pure.

(Patent Number 3198125)